Multisensing

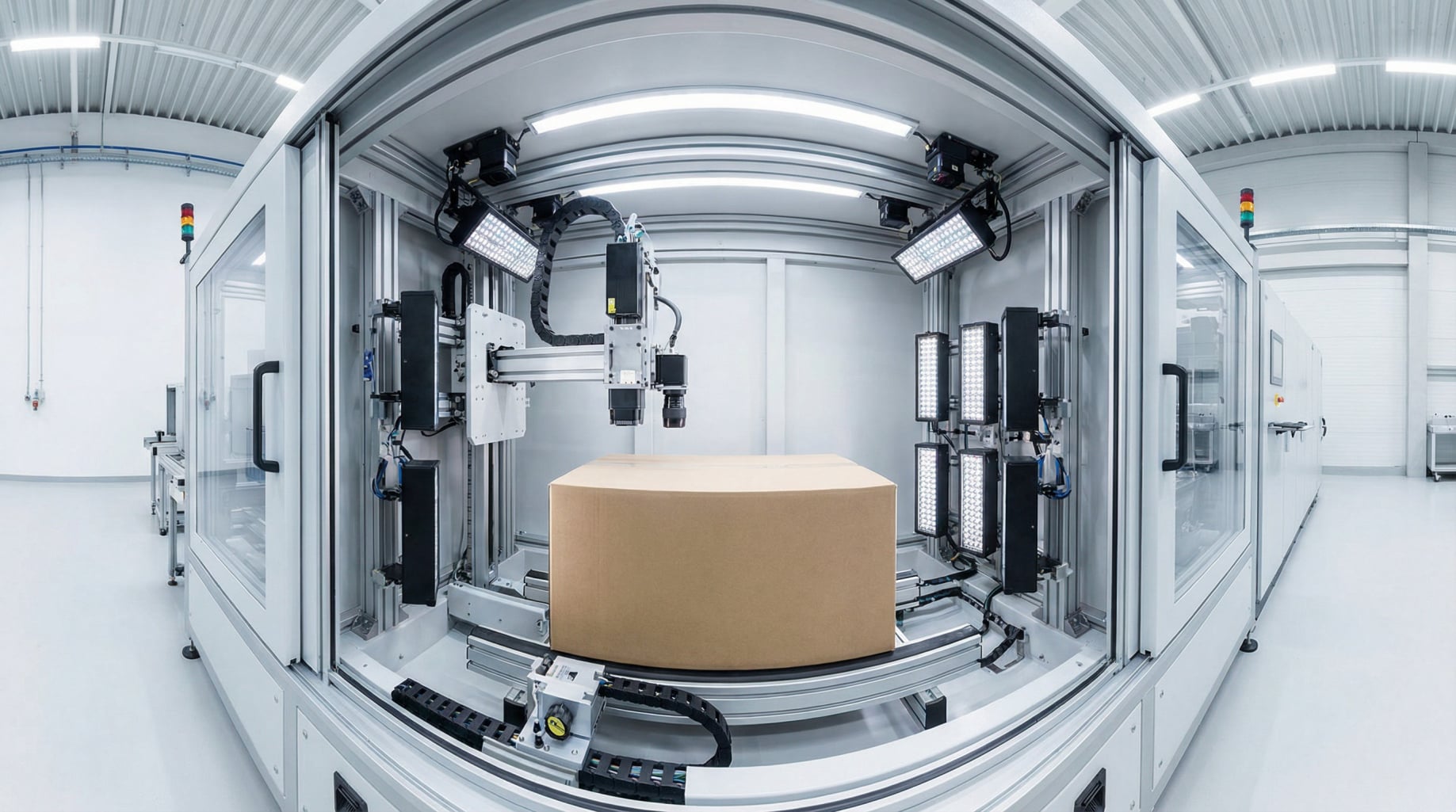

360° Vision

Fully Adaptable

100% Automated

30% Efficiency Improved

70% Waste Reduced

Industries

Benefits for you

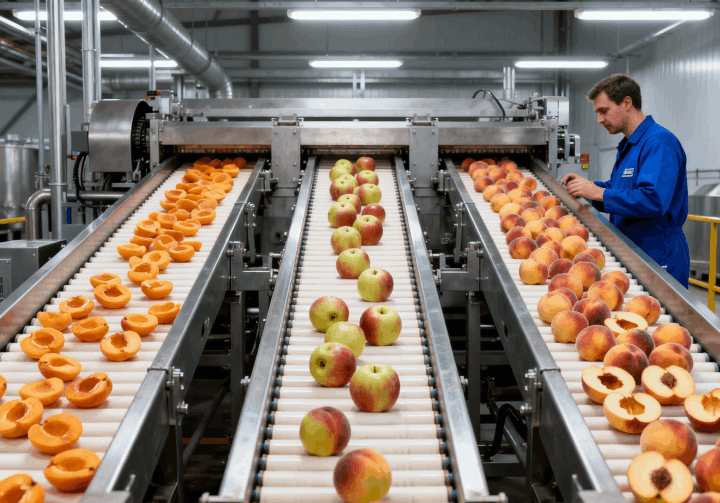

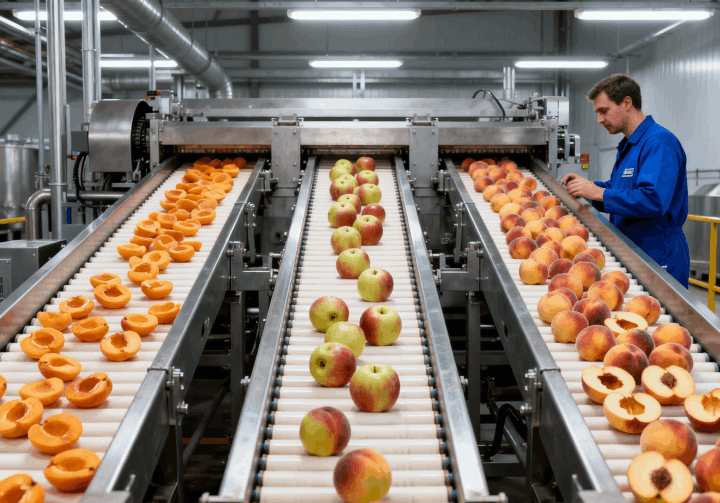

Automated Quality Assurance

Streamline your production with real-time, automated inspection systems that guarantee product compliance and reduce reliance on manual checks. Capture and document quality data for every item with precision, ensuring consistent standards across your entire output.

Read More

Leverage Quality Insights

By automating and digitalizing inspections, manufacturers unlock valuable data on production trends and performance. Actionable analytics and process feedback enable continuous optimization, helping to fine-tune operations and drive higher efficiency.

Read More

Minimize Waste, Maximize Savings

Implementing accurate inline inspection reduces the risk of defects reaching the market, cutting costs tied to recalls and rework. Early issue detection and data-driven root cause analysis help streamline operations, reduce material waste and lower overall QC expenditure.

Read MoreComputer Vision Passion

Success Stories

R&D Manager - Textile Industry

Processing Engineer - Food

Operations Manager - Electronic

We will be happy to answer you