Precision from Thread to Finish

Flawless textiles, leathers, and interiors—inspected at every stage.

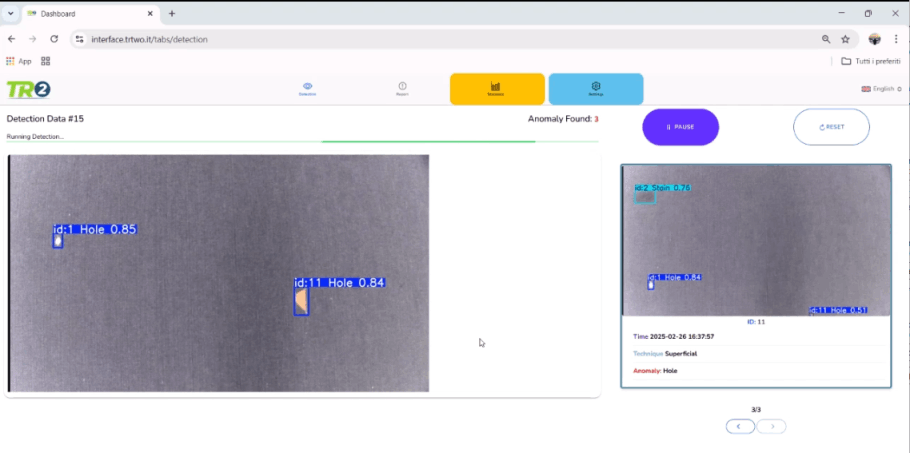

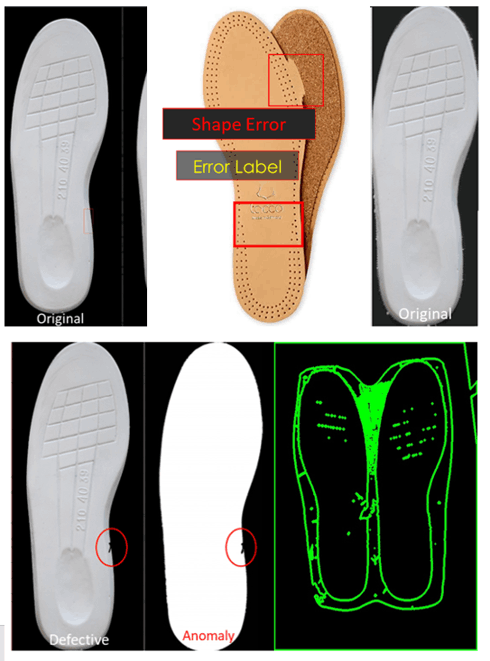

From woven fabrics to premium hides and technical materials, ensuring surface quality and consistency is key. TR2’s computer vision systems detect weaving flaws, surface scratches, holes, color inconsistencies, and texture anomalies—automatically, in real time.

This enables producers to reduce manual inspection, minimize rework, and guarantee quality for end uses across fashion, furniture, and automotive interiors. The result? Higher efficiency, fewer defects, and elevated customer confidence from roll to final application.