Consistent Quality, Even with Nature’s Variability

Natural products vary—our AI helps you ensure uniform quality anyway.

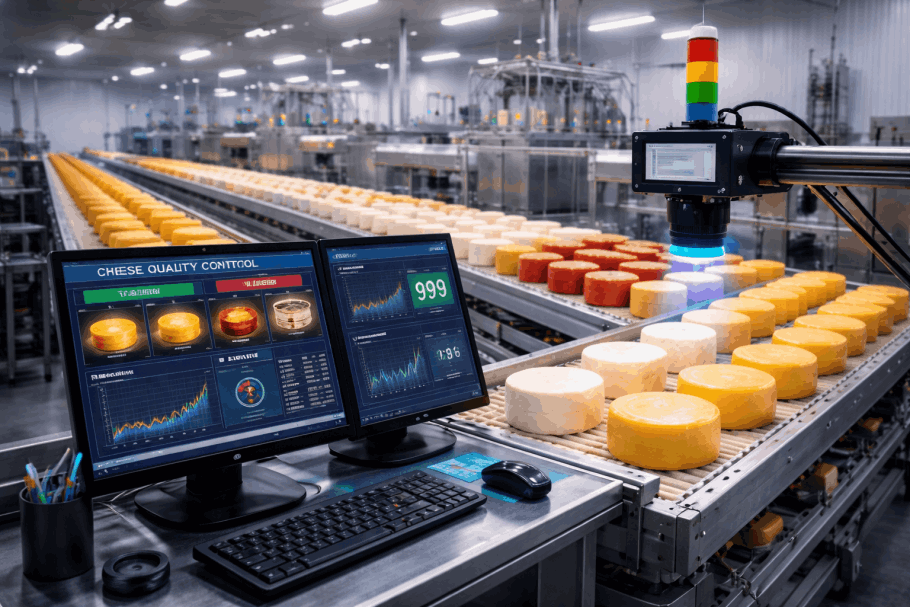

Ensuring consistent product quality across batches is a daily challenge for food processors.

TR2’s computer vision systems inspect every item on the line in real time—detecting defects, sorting by grade, and flagging anomalies. This enables manufacturers to maintain strict standards and deliver uniform quality, despite nature’s unpredictability.